Top 8 IoT trends and predictions for 2019 (Infographics)

Capitalizing on technological advancements in industrial manufacturing, companies are taking bolder steps to improve growth and operational efficiency in 2019. It is expected that technology spend worldwide on the Internet of Things will reach $1.2 trillion by 2022. The companies are finding ways to solve the complicated problem of blending all production systems – IT and OT data, quality management, Production processes, and Business Intelligence into a single data model. The adoption of IoT services and devices is set to hit 20% higher in 2019.

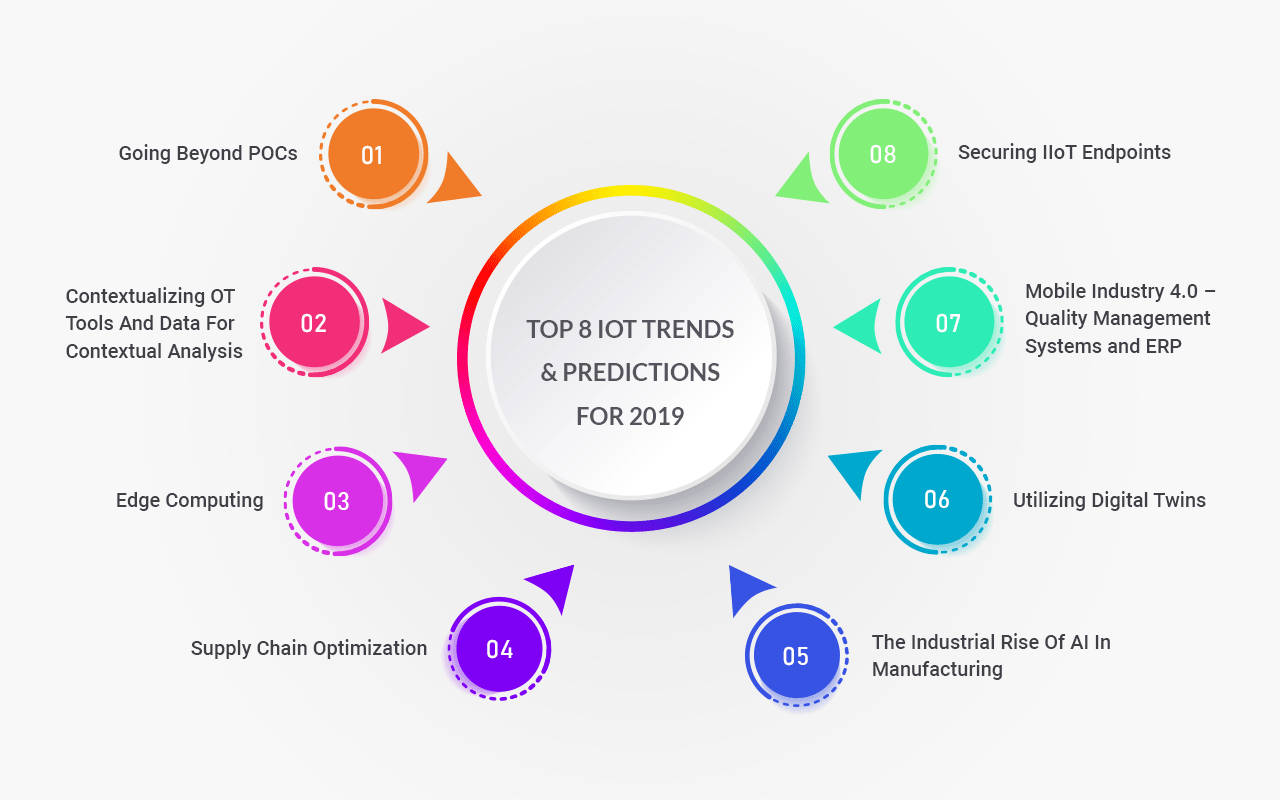

Here is an infographic on the top predictions and trends for IOT in the upcoming years.

Top 8 IoT trends and predictions for 2019:

Going beyond POCs:

It’s expected that 2019 will be the year, where investors move from IIoT (Industrial Internet of Things) proof of concepts to extending pilots for industry 4.0 solutions, namely digital twin, predictive quality, and predictive maintenance.

Contextualizing OT tools and data for contextual analysis:

IT and OT (Operational technology) have been raising for the past few years, and integrating is converging as the goal. Many of the investors are taking their IT and operational data a step forward to enhance the accuracy and relevancy of the data-driven insights.

Contextualization is the next step. The only way for the investors to reach accurate conclusions, measure the right data, is by integrating all the relevant OT data from the line or plant environment with context data of the business from the IT systems.

The contextualization of OT data happens with dimensions like production recipes, quality test results; production process flows, product, and batch details.

Edge Computing:

The investors will take the benefits of AI capabilities and local data processing (Edge computing). IoT devices and sensors will generate about 5.07.5 zettabytes of data by 2020.

Edge computing enables businesses by storing and analyzing data relevant to its source to reduce time and expenses regarding enhancing data security and data analytics.

Supply chain Optimization:

The online consumer trends have changed the expectation of customers for transparency, efficiency, on-demand services, speed, and more. Supply chain 4.0 is a crucial way to shift the supply chain landscape and meet new demands through digitization. Mobile apps, AI-powered predictive tools, and digital twins are top industry 4.0 trends for 2019.

Artificial Intelligence will be embedded in different processes of the supply chain to increase accuracy, flexibility, and rapidness.

The industrial rise of AI in Manufacturing:

Industrial IoT and AI are integrated into digitizing the process of production to decrease downtime and enhance productivity. Machine learning algorithms for industrial manufacturing are tailored to increase process stability, eradicate process disturbances, minimize unplanned downtime, and to decrease production waste in any specific product lines.

Utilizing Digital Twins:

A recent survey indicates that 24% of the business has already started executing IoT solutions and Digital Twins to enhance efficiency and safety, and the number is about to increase based on the Gartner survey.

In 2019, Digital twin will see an expansion in their use, and more digital twins will be used for optimizing the production processes. The full digital twins will create process data, and this will enable investors to reach more flexible insights, whether by viewing the high-level process architecture or deep-diving into individual machines to recognize and address inefficiencies in manufacturing.

Mobile Industry 4.0 – quality Management Systems and ERP:

The arrival of 5G next generation mobile networks indicates higher creation of IIoT applications. Because of the 5G and other technological advancements in the mobile tech, this year will see a massive rise in the use of IIOT and in real time applications once excluded from direct interactions along with the industries involved.

Securing IIoT Endpoints:

The organizations have already invested in protecting their OT infrastructure, as similar to the same degree as they do to their Information Technology systems. Regardless, the present and clear threat to the business cybersecurity, integrated with the boom in the adoption of industrial IoT applications will see ICS security and OOT security go mainstream in plants manufacturing, whatever the industry or size.

About IntellectFaces:

IntellectFaces make use of the Internet of Things Integration to have more consumers as well as for doing better business. Contact us to know more about IOT Integrations.